As the name implies, a Volumetric Cup Filler Machine is a filling machine that uses a volumetric cup to measure.

So how does it work? What are its features? Let me introduce you to the following

The Overview of the Volumetric Cup Filler Machine

The volumetric cup filler uses cups to measure how much product is needed and then pours it into the container. It is suitable for filling powders and has certain requirements on the characteristics of the powder. Your products need to be uniform, free from dust, flow well, not stick to things, and not be easily affected by moisture.

Since it is a volume measure, powders that have non-homogeneous particles will cause the weight of the product in the container to be different from the desired amount. And powders that don’t flow well, stick easily, or are easily affected by moisture will jam the machine. This makes the filling efficiency lower and makes the machine less accurate.

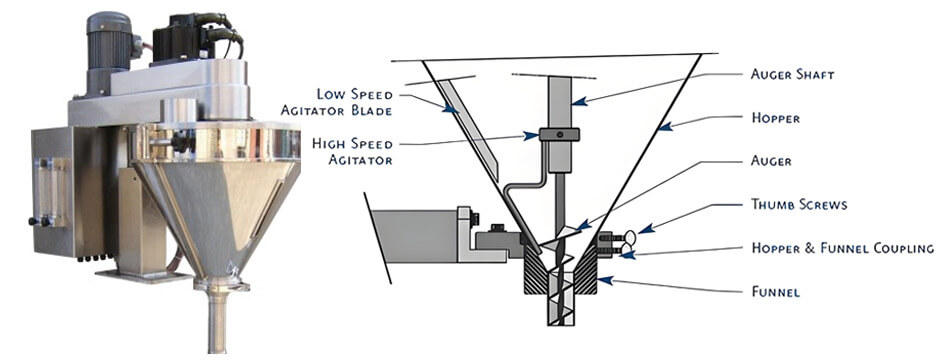

Working Principle of a Volumetric Cup Filler Machine

Volumetric cup filling is a volumetric filling method that uses a measuring cup.

First, you need to determine the amount of the product. The volume of product to fill each cup is measured with a calibrated syringe. It is then dispensed into each cup at a high speed. As they rotate to the top of the cycle, a mechanism levels off the contents. This is the key to keeping it consistent. The plate continues to rotate and when the filled cups reach the fill spout, the product drops through the container below.

Volumetric cup filling is fast, usually faster than auger fillers. They can fill 30 to 80 bags per minute. However, it is not as accurate as the weight-measurement filling method. If you want to increase accuracy, you can choose a volumetric cup filling machine with weighing equipment.

The control system of the volumetric cup filler machine is also simple. You can adjust the filling rate without any effort.

Volumetric Cup Filler Machine Features

Easy Operation

The cup volumetric filling machine has a simple control panel. The entire machine has no complicated structure. It makes the operation easier with the control panel. Plus, the pneumatic control reduces the need for you to manually operate the machine.

Speed

The volumetric cup filler machine is simple in structure and operation. By rotating the plate, you measure out the powder product and pour it into the measuring cup. The plate continues to rotate. When the fill cup reaches the fill spout, the product is poured into the container. And, many machines come with integrated maintenance services to help you minimize downtime and keep your machine running smoothly. The volumetric cup filler machine can fill hundreds or even thousands of packages per hour. Ideal for mass production.

Accuracy

If your product is not a non-free-flowing powder and is not susceptible to moisture or sticking, then you can use a volumetric cup filler machine to fill powder products with a relatively high degree of accuracy. Although it is not as accurate as an auger filler, it is only off by up to 1% of the target weight. You can also choose to use volumetric cup filler machines with weighing equipment to increase the accuracy.

Flexibility

You can adjust the size of the measuring cup to fit the amount you need to fill. This allows you to pack many different products. You can also adjust the filling speed to fit your different needs.

Cost

The volumetric cup filler machine is very simple in structure. So the initial investment and maintenance cost is low. And it has a modular design for easy cleaning and maintenance.

Durability

Volumetric cup fillers are durable and are usually made of stainless steel or other strong materials.

The Application of Volumetric Cup Filler Machine

Volumetric cup fillers are suitable for filling free-flowing, regularly shaped, dry granular products. They are used in many industries.

| Industries | Porduct Examples | Product Feature |

| Food, Drink and Condiment | rices, sugar, salt, nuts, beans | free flowing, dry, regular shape and size, granular |

| Chemical Industry | fertilizers, detergents | |

| Cosmetic Industry | bath salts, body powders |

Conclusion

The products to which the Cup Volume Filler corresponds are very clear. It is a good choice if you want to fill free-flowing products. Easy to operate, has a certain flexibility and guarantees both speed and precision.