For detergent manufacturers, packaging is more than just a container—it’s a key factor in brand positioning, consumer convenience, and production efficiency. Whether you make powder detergent, liquid detergent, or detergent pods, the right packaging solution keeps your market competitiveness and cost-effectiveness.

This guide will cover:

- The most common detergent packaging formats.

- Their advantages and applications in retail and wholesale markets.

- The detergent packaging machines required for each format.

- How to select the right solution for your business.

Why Detergent Packaging Matters

Detergent packaging must balance functionality and branding. A strong solution should:

- Protect product quality (moisture barrier for powders, leak-proof for liquids).

- Ensure convenience (easy pour, resealable closures, single-dose pods).

- Support sustainability (eco-friendly films, recyclable bottles, lightweight pouches).

- Stand out on shelves with professional printing and attractive designs.

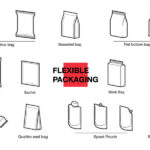

Market Insight: Flexible packaging (pouches, sachets) is rapidly growing in detergent markets due to lower cost, reduced plastic use, and easier logistics.

Popular Detergent Packaging Formats

1. Plastic Bottles & Jars

- Best For: Liquid detergent, gel, or concentrated formulas.

- Advantages:

✔ Durable and leak-proof.

✔ Easy to use with caps, pumps, or measuring caps.

✔ Supports large volumes (1L – 5L+).

2. Sachets (Single-Serve Packs)

- Best For: Powder detergents and liquid detergent samples.

- Advantages:

✔ Extremely cost-effective.

✔ Portable, convenient for small budgets and single-use.

3. Pillow Pouches

- Best For: Powder detergents in retail packs (100g – 5kg).

- Advantages:

✔ Low-cost, high-volume packaging option.

✔ Efficient for automatic filling lines.

✔ Suitable for supermarkets and wholesale distribution.

4. Stand-Up & Spouted Pouches

- Best For: Liquid detergents and refill packs.

- Advantages:

✔ Lightweight and eco-friendly.

✔ Easy to store and transport.

✔ Reclosable with spouts for convenience.

5. Pods & Water-Soluble Films

- Best For: High-end detergent capsules.

- Advantages:

✔ Pre-measured doses, no mess.

✔ Attractive, premium product appeal.

✔ Growing rapidly in North America & Europe.

6. Cartons & Boxes

- Best For: Large-volume powder detergents and as secondary packaging for smaller packs.

- Advantages:

✔ Rigid and stackable for easy transport.

✔ Allows premium branding and full printing space.

✔ Protects inner packaging like sachets, pillow pouches, or pods.

Common Application: A box containing 10–30 detergent sachets, or a family pack of pods sealed inside an inner liner for moisture protection.

Types of Detergent Packaging Machines

1. Bottle Filling & Capping Machines (for Liquid Detergent Bottles)

- How It Works:

- Bottles are fed onto a conveyor.

- Servo-driven piston fillers or gravity fillers dose the liquid detergent.

- Automatic cappers apply screw caps, pump caps, or dosing caps.

- Optional labeling and shrink sleeve applicators finish the packaging.

- Bottles are fed onto a conveyor.

Best For: Medium to high-volume detergent manufacturers producing PET or HDPE bottles.

2. Stand-Up & Spouted Pouch Packaging Machines (for Liquid Detergent Pouches)

- How It Works:

- Pre-made stand-up pouches with spouts are loaded.

- A filling system (usually piston filler) injects liquid detergent.

- The bag opening is cleaned to remove residual detergent and sealed for output.

- Pre-made stand-up pouches with spouts are loaded.

Best For: Brands offering eco-friendly refill packs or premium concentrated detergents.

3. Vertical Form Fill Seal (VFFS) Machines (for Powder Detergent Pillow Pouches)

- How It Works:

- Film is formed into pillow pouches by the VFFS machine.

- Auger fillers or cup fillers dispense detergent powder.

- The pouch is heat-sealed and cut.

- Film is formed into pillow pouches by the VFFS machine.

Best For: High-speed, large-volume production of detergent powder packs (100g to 5kg).

4. Sachet Packaging Machines (for Single-Serve Detergent Packs)

- How It Works:

- Film is formed into small sachets (stick pack or flat).

- Auger fillers (powder) or liquid pumps (liquid) inject detergent.

- Sachets are heat-sealed and cut.

Best For: Small packs of powder or liquid detergent.

Pro Tip: Multi-lane sachet machines allow high output for mass-market single-use detergent packs.

5. Detergent Pod Packaging Machines (for unit-dose detergents)

- Best For: Laundry pods and dishwashing capsules.

- How It Works:

- Water-soluble PVA film is thermoformed into small cavities.

- Machines fill them with concentrated liquid detergent.

- A second PVA film layer seals the pod.

- Water-soluble PVA film is thermoformed into small cavities.

- Special Requirement: Must work in temperature and humidity-controlled environments to protect PVA films.

6. Detergent Cartoning Machines (secondary detergents packaging)

- How They Work:

- Carton forming & folding: The machine erects flat cartons into box shape.

- Filling: Sachets, pillow pouches, or pods are automatically counted and inserted.

- Sealing: The carton is glued or tucked shut.

- Printing/Labeling (optional): Barcodes, batch numbers, or branding applied.

- Best for: Secondary packaging, where smaller primary packs (pillow pouches, sachets, pods) are automatically placed into cartons or boxes.

Choosing the Right Detergent Packaging Machine

| Packaging Format | Recommended Machine | Best For |

| Pouches (pillow, stand-up, spouted) | VFFS / Premade pouch filler | Powder & liquid detergents |

| Bottles & jars | Bottle filling & capping line | Liquid detergents, gels |

| Sachets (small packs) | Multi-lane sachet machine | Single-use packs, samples |

| Pods / Capsules | Detergent pod forming & sealing machine | Premium detergents |

| Cartons & boxes | Carton filling & sealing line | Secondary detergent packaging |

Conclusion: Making the Right Choice

The right detergent packaging machine depends on:

- Your product type (powder, liquid, pod).

- Your target market (cost-driven vs premium eco-friendly).

- Your production scale and automation needs.

For low-cost mass production, sachet and pillow pouch packaging machines are ideal.

For large-scale factories, fully automated VFFS, premade pouch filler, or bottle filling lines ensure efficiency and scalability.

Need customized detergent packaging solutions? Contact HonorPack today!