When you think of powder filling, you definitely think of the auger filler. It is often the first choice for powder filling. It quantitatively dispenses the product into the container through the rotation of the auger, improving the efficiency and precision of powder filling. It is widely used in pharmaceutical, food, cosmetic and chemical processing industries. Next, I’ll give you an overview of its operation process and specific components.

What is Auger Filler

Auger fillers dispense products using the auger, which is a device that conveys material through rotation. It measures the amount of product required to be added to the container accurately, with a very small inaccuracy of less than one percent. Widely used for filling free-flowing and non-free-flowing products such as salt, sugar, flour, cake mixes, etc., it is particularly suitable for filling powders. Whether the particles are of uniform or inconsistent size, large or small, the auger filling machine is the perfect choice for them. Auger metering is fast and efficient, so if you’re packing powders, this is a great choice for you.

Working Principle of Auger Filler

The material is fed into the hopper, and the agitator blade mixes the material evenly by rotating to ensure that the product enters into the auger evenly.

The agitator blade are designed to extend all the way to the funnel, and this design can prevent rat-holing and cavitation. These two terms may be new to you.

Let’s put it this way: rat-holing is the formation of a narrow channel within the material in a silo or hopper. And the material can only flow through this channel, while most of the surrounding material remains stationary. This problem is most often seen with cohesive or non-free-flowing powders, such as milk powder and flour. These powders tend to stick together and to the walls of the hopper, resulting in restricted flow and inefficient conveying.

Cavitation is the formation of voids or empty spaces in the material flow system, resulting in poor, uneven and inefficient material flow.

Agitator blade’s role is obvious, it can ensure that the material will not stick to the walls of the hopper, so that the material flow is consistent without air spaces, to ensure the stable filling of the auger. The agitator blade are driven by a separate servo motor. Therefore, you can easily control its speed, and it rotates in the opposite direction to the auger.

The auger drive keeps the auger rotating at a constant speed. So, you might ask if the constant speed of the auger is the reason auger fillers dispense material into containers quantitatively. Of course, that is one of the reasons. It’s also because the auger has a consistent pitch and the same size of auger screw. The larger the auger, the greater the amount of powdered material dispensed per revolution. Auger fillers with small pitch and small auger screw control the flow of material more accurately. Auger fillers with large pitch and large auger screw are suitable for applications requiring high throughput. By means of the auger blade, the material is dosed and guided into a funnel to be dispensed into containers.

Main Parts of Auger Filler

Drive Assembly

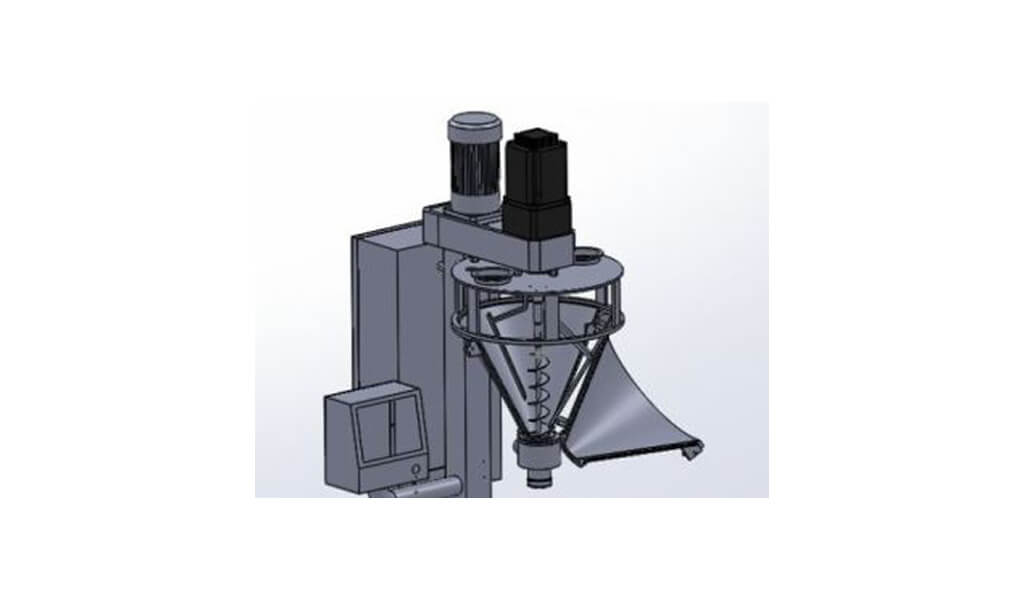

The drive assembly of the screw filling machine facilitates the filling machine to realize reliable filling operation. The drive assembly mainly consists of servo drive and transmission mechanism. The drive assembly consists of two independent motors that control the rotation and speed of the auger and the rotation and speed of the agitator blade. The assembly can be electric, hydraulic or pneumatic.

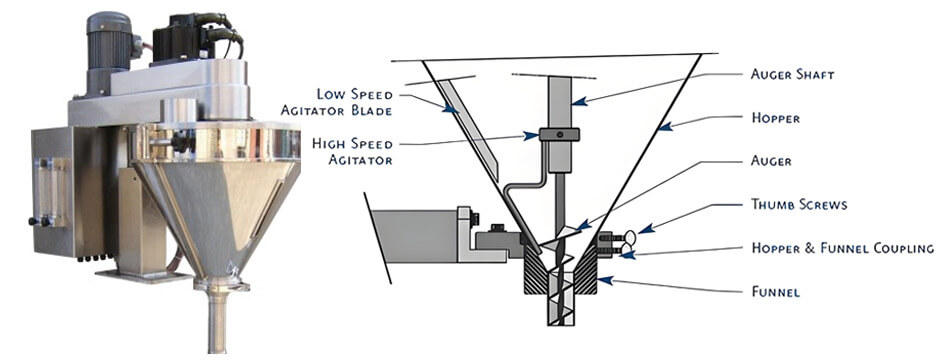

Hopper

The hopper is the storage area where the material is held before it is screwed into the container and is usually made of 304 stainless steel, which can be replaced with 316L stainless steel if corrosive environments are involved. It is a split design with quick release clamps for easy cleaning and maintenance. Some hoppers come with a viewing glass through which you can inspect the inside of the hopper.

Tooling

The tooling part lies at the center of the performance of an auger filling machine. It consists of the auger, agitator blade and funnel. All are replaceable units that you can change as you need.

- Auger: It rotates vertically in the hopper and directs the material out of the funnel. The speed of the auger can be adjusted according to your needs.

- Agitator blade: The agitator blade mixes the material evenly by rotating to ensure that the product enters the spiral blades evenly. Guiding the product to the auger, it rotates in the opposite direction to the auger. You can also adjust its rotation speed according to your needs.

- Funnel: The funnel is the discharge port of the screw filling machine that guides the product into the container and it is where the product is dispensed. Depending on your needs, you can customize the funnel. For example, you can customize a funnel with adjustable gates or other flow control to regulate the flow of product into the container.

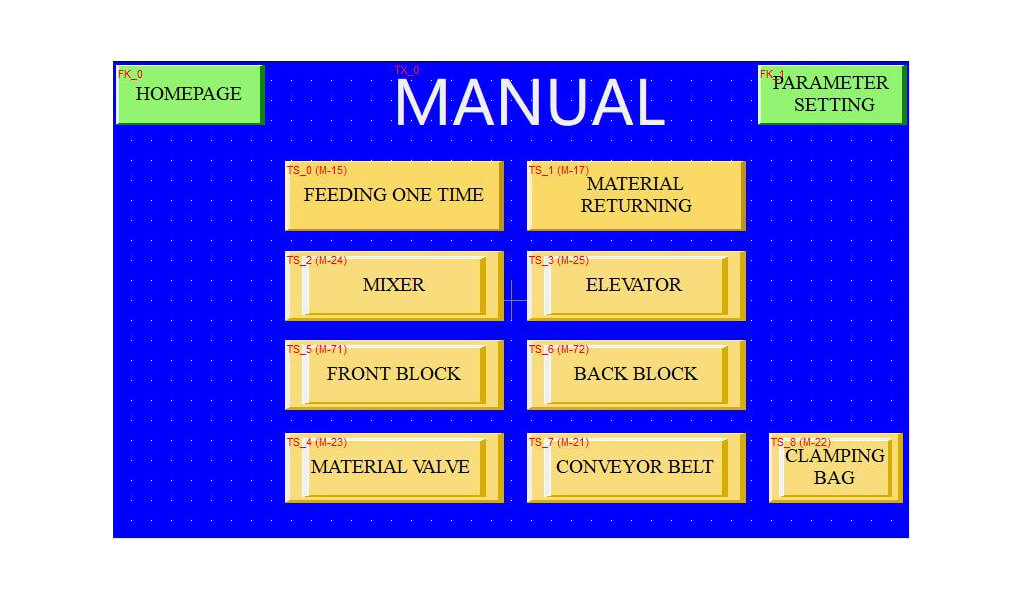

Control Panel

The control panel, as the name suggests, allows you to adjust various parameters of the auger filling machine. For example, auger speed, fill volume and filling speed. You can adjust them according to the characteristics of the product and your needs. Some machines are also equipped with a PLC-based touch screen to make your operation more convenient and the operation speed is improved.

Conveyor Belt

Conveyor belts are familiar to you as a device used to move filled products from one station to another. It is usually equipped with container holds, variable speed controllers, photoelectric sensors and adjustable guide rails. The application of conveyor belts greatly improves the automation level of auger filling machines.

Compressed Air System

Compressed air systems are used to control the pneumatic components of machines, such as the drive mechanism. The compressed air system regulates the flow rate of the product. It helps to ensure that the screw filling machine fills reliably and consistently.

Types of Auger Filler

Semi-Automatic Auger Filler

Semi-automatic screw fillers are machines that need to be operated manually, but they are very simple to operate. The operator needs to place the container under the outlet for filling and usually the machine has a foot pedal, which is equivalent to a feeding switch.

Automatic Auger Filler

The automatic auger filling machine, on the other hand, does not require manual operation. It is able to perform various operations automatically and can fill more quickly and more accurately. The automatic screw filling machine would know when the product has been filled. At that time the product can be moved to the next place via a conveyor belt. It is widely used in large-scale production lines for food, pharmaceuticals, and so on.

Dual Auger Filler

The dual auger filling machine is equipped with two augers, one for coarse filling and the other for precise filling.

Multiple Auger Fillers

The multiple auger filler has multiple filling heads for faster and more efficient filling.

Conclusion

If you are interested in powder filling, then it is better to have a detailed understanding of the screw filling machine beforehand. Including its operating procedures and important components. This will help you to choose what kind of auger filling machine or what kind of parts to replace.