Whether you are a beginner or an industry veteran in the pet food packaging business, this comprehensive guide will make you an industry expert.

Well, if you want to maintain pet food quality, you need to choose a packaging option based on the product’s material and food types. Also, you can select a specific packaging machine for filling or sealing.

Let’s dive straight to the section below to learn more about pet food packaging-

What Is Pet Food Packaging?

Pet food packaging is a layer of protectors for storing pet food. This keeps the product safe and makes transporting it easy. It comes in various forms, such as bags, pouches, etc. The packing material of the pet food is chosen based on the product’s kind, its shelf life, and its efficiency for pet owners.

So, with pet food packaging, you can ensure product quality, prevent contamination, and provide product information.

Types Of Pet Food Packaging

I have included the four types of pet food packaging in this section. Check them out-

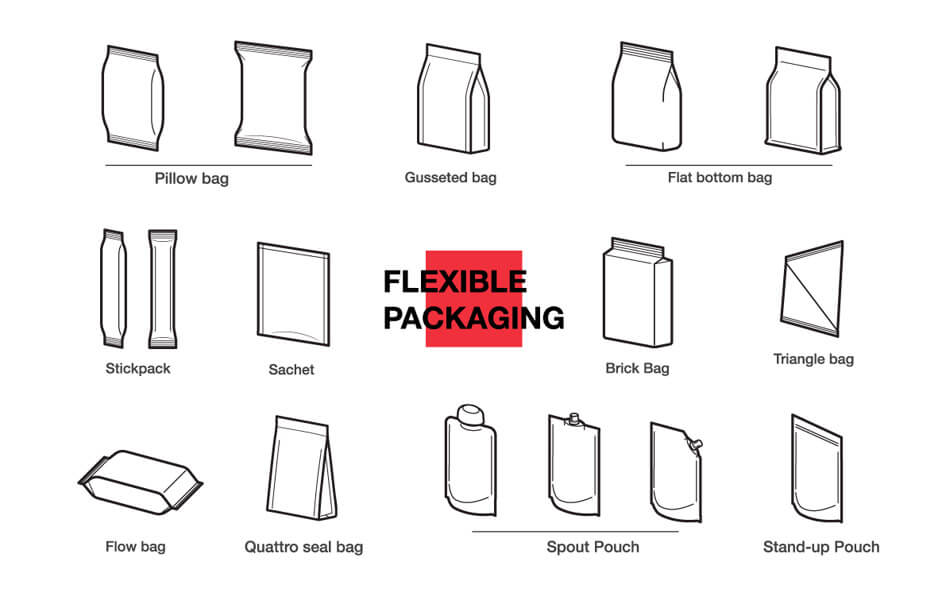

- Pouches

These options are well-known among customers for pet food packaging. They are lightweight, easy to store and open, and often resealable. Also, pouches come in various shapes and can match the product portion.

Additionally, pouches require less energy than rigid containers. You can print them with unique colors and designs; they can easily attract customers. Therefore, packaging pouch bags are an excellent choice for practical food packaging.

| Pros | Cons |

| Convenient and flexible Made from multi-player materials Offer strong barriers against moisture | Hold limited quantities of products |

- Jars

Jars are a traditional and appealing choice for pet food packaging. They are made from glass or plastic. These types can protect food against moisture, ensuring the product’s freshness.

Besides, jars are transparent, so the customers can see what they purchase. It will build trust between consumers and sellers.

| Pros | Cons |

| Often comes with screw top lids to make it easy to open Environmental friendly Reusable and recyclable | Heavy to carryGlass jars are fragile and expensive |

- Stick Packs

Stick packs are modern and ideal for single-serve portions of pet food or treats. These slim packets are easy to carry and perfect for travel or on-the-go feeding. Stick packs protect the contents from the air and maintain quality. Therefore, you can use them to store liquid supplements, wet food, or powdered products.

Furthermore, stick packs are easy to tear open, offering a mess-free experience. Due to their minimal material usage, they reduce packaging waste. Also, they use minimal materials, about 40% less than conventional ones.

| Pros | Cons |

| Compact and portable Best for hold to accurate portion Easy to carry and use | Limited designNot all types of products are suitable |

- Can (Aluminium Can, Tin Can, Plastic Can)

Cans are made from aluminum, plastic, and tin. You should choose one material based on your product requirement, as each one has specific benefits. For instance, aluminum cans are lightweight and have excellent barrier properties. They can keep food fresh and extend its shelf life.

However, tin cans are heavier and more robust, offering reliable protection. On the other hand, plastic cans are much lighter than others and easy to carry.

| Pros | Cons |

| Durable and versatile Offer airtight sealHas a long shelf life Simple to transport and store | Cans cannot be resealed |

Materials Used In Pet Food Packaging

Materials can be different types depending on the pet food packaging requirements. To get a proper idea about pet food packaging materials, take a look at this section-

Plastics

Plastics are popular in pet food packaging design among customers worldwide. These materials can protect pet food from oxygen and moisture. They have different types, such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET).

PE is a flexible pet plastic food packaging option. Meanwhile, PP is best for withstanding high temperatures. On the other hand, PET is strong and can prevent moisture. Although plastic packaging can impact environmental pollution, improving recyclable options will be helpful.

Paper And Cardboard

Paper and cardboard are cost-effective and best for your low-budget plan. These materials are often used for outer packaging, such as boxes. They offer moderate protection against external elements. You can easily customize them based on your branding ideas and preference design.

Moreover, paper bags are recycled. However, these materials do not provide as much barrier protection as metals or plastics.

Metals

Metals, such as aluminum and tin, are often used for pet food packaging. Aluminum protects against light and oxygen and preserves pet food’s nutritional value. Tin used in cans offers similar benefits and adds a layer of protection.

Furthermore, both are environmentally friendly, as they are recyclable. They also keep pet food fresh and resistant to external factors.

Composite materials

Composite materials combine different substances, such as paper, plastic, and metal layers. They are designed to provide superior barriers against light, moisture, and air. Therefore, composite materials can ensure pet food nutrition and freshness.

Moreover, they are designed to be recyclable or biodegradable. Integrating multiple layers offers a balance of durability and protection. Also, these materials are mostly lightweight and reduce transportation costs.

Factors To Consider While Choosing Packaging Materials

Customizability: This is essential if you have specific requirements for packaging. This option allows you to customize the packaging materials’ shape, size, print, and colors. So you can choose size and shape based on products and print your brand identity and production information. For instance, you can print the brand name or logo on one side of the package and the ingredient and nutrition level on the other side. Therefore, try to make unique custom pet food packaging packaging that will differ from competitors.

Cost-Effectiveness: If you have a small business and a low budget, choose paper or plastic materials. This will ensure cost-effective and profitable production. You can also consider bulk purchasing, which often offers low prices.

Preservation of Freshness: Choose packaging materials that protect and preserve the product’s freshness and nutritional value. Materials like laminated films can prevent moisture and air and keep the food fresh.

Sustainability and Environmental Impact: By selecting eco-friendly materials for pet food, you can reduce pollution and improve your brand’s reputation. So, paper and glass bottles packaging materials as they are recyclable.

Why Is Pet Product Packaging Important?

The main essentials of packaging are to protect pet food from mold and keep it fresh for a long time. At the same time, the packaging makes it easy to transport. Also, with a clear package, you can include product information for the consumer.

- Safety: Packaging is necessary to preserve and protect pet food from harmful substances. This way, the pet food is safeguarded against tampering and accidental exposure.

- Branding: Pet product packaging can enhance your brand identity. You can create specific packaging with logos, designs, and colors. It will attract the pet owners and boost sales.

- Preservation: Preservation is critical to ensuring the quality and freshness of your dog and cat food. The packaging allows you to save the product for a long time.

- Information: On the package, you can include the cat and dog food ingredients and nutritional level so the pet owners can read everything and decide whether to purchase.

- Convenience: Easy-to-use and store packaging increases user experience. This way, you will make repeat consumers.

What Are The Pet Food Packaging Machines?

Premade Pouch Packaging Machines: Premade packing machines automatically pour the pet food into pouches. This pet food packaging machine packs a wide range of pet food products and seals around 60 to 100 bags in a minute. If you have already made pouches, you can use this equipment to pour food.

Vertical Packaging Machines (VFFS): VFFS machines can create approximately 50 to 150 bags each minute directly from roll film based on the machine and product size. They are also efficient for high-speed production and ensure airtight sealing.

Semi-Automatic Big Bag Bagging Machines: You can use semi-automatic equipment for mass packing. Operators fill the bags manually, and the machine automatically seals and discharges up to 15 bags per minute.

Jar Filling Machines: With jar-filling machines, you can accurately fill products into around 20-45 plastic or glass jars in a minute. These automatic machines can operate quickly, reduce work time, and handle various jar sizes.

Can Filling and Sealing machines: They pour pet food into cans at high speed up to 20 to 80 cans each minute. These machines provide accurate packing and robust caping. Depending on the machine model, they can fill it out.

Right Packaging For Dry & Wet Pet Food

Dry Food: The ideal packaging for dry food that maintain freshness, taste, and nutritional value. Multi-layer films or foil laminate bags provide a barrier against the air and moisture of the pet food. Besides, pouches’ proper sealing and tamper-evident features ensure dry pet food quality for up to 12 months.

Wet Food: Cans or vacuum-sealed pouches are best for wet pet food packaging options. They ensure quality and prevent pet food contamination. Also, they provide airtight seals, extending the product’s shelf life for 2 to 3 years.

Conclusion

Now you know all the details about pet food packaging. Keep this information in mind while choosing and running your pet food packaging business. If you want the best pet food packaging solution, contact HonorPack now. We have a wide range of packing equipment for different kinds of pet food.

FAQs

What do pet owners seek in pet food packaging?

Pet owners seek packaging that guarantees food quality. They also look for packaging with resealable options and easy-to-open designs. So they can simply open and store the food without any hassle.

What are the disadvantages of pet food packaging?

The key drawback of pet food packaging is the non-recyclable materials, which pollute the environment. Also, contamination can occur in the pet food if the packaging is not sealed correctly. Some packaging options are less user-friendly for pet owners.