Confused about IP rating while purchasing your packaging machine? Let me help you.

Well, the perfect IP rating depends on your working environment. For instance, if you work with powder, snacks, or other products, choose a dust-resistant machine.

In this article, I have discussed everything about IP ratings, from what they are to how to choose the right one.

What Is IP Rating?

When you purchase a packaging machine, you should know its IP rating. So what is IP rating? Well, IP means Ingress Protection and this also refers to International Protection. It indicates machines’ capability to resist dust, water, harsh weather, or any unwanted accidents.

More specifically, the IP rating has two digits on the mechanical or electrical machine. The first number represents protection from solids, and the second one means water resistance. Understanding this rating can help you buy a machine that matches your requirements.

IP Rating Chart Breakdown

In this section, I have discussed IP rating with charts that will help to get a proper idea about it. Check them out-

- First Digit: Solid Resistance

The first digit or number in the IP rating refers to the machine’s ability to resist solid and accidental contact with moving parts of the machine.

| Level | Dust protection |

| X | It means data not available |

| 0 | No protection |

| 1 | Save from 55mm or more extensive surfaces like a hand |

| 2 | It means protected from 12.5mm object |

| 3 | Protection against 2.5mm tools and screws |

| 4 | This can handle 1mm small tools and more |

| 5 | Partial dust protection: dust can get into the machine without harming the device |

| 6 | No dust can enter at all |

- Second Digit: Liquid Resistance

This second digit indicates the machine’s capability to tolerate water from a drop of rain to complete immersion. Take a look at them-

| Level | Water protection |

| X | It indicates no data is available |

| 0 | Not Protected |

| 1 | Save from dripping water like rain |

| 2 | Protection against vertical angle 15 degrees off |

| 3 | Protected from spraying water comes from any direction more than 60 degrees |

| 4 | It indicates save from splashing water from all angles |

| 5 | Protection against low-pressure water jets from any direction (like a garden hose) |

| 6 | This means saving from strong water jets |

| 7 | Protection against immersion up to 1 meter |

| 8 | Protection from the continuous immersion of water beyond 1 meter |

- Additional Letters

Often, some additional letters also appear with an IP rating. Each letter refers to a different meaning; check them out here-

| Letter | Meaning |

| f | Oil protected |

| H | High voltage machine |

| M | Tested for water ingress with moving parts |

| S | Tested with water and the machine standstill |

| W | Suitable for outdoor use |

IP Rating Found On Packaging Machines

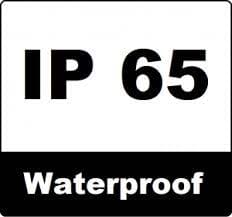

- IP65: This rating prevents dust from entering the packaging machine and allows it to withstand water jets at low pressure.

- IP66: Totally protected from dust and handle powerful water jets.

- IP67: Also, this refers to complete protection against dust. On the other hand, the machine is safe while sinking into 1 meter of water.

- IP68: The packaging machine is entirely safe from dust and can be immersed in 1.5 meters of water.

Why Is IP Rating Important For Your Packaging Machine?

Let’s look at a few of the reasons why IP rating is essential for the packaging machine under three conditions. So you need to take into account while purchasing a packaging machine-

Wet conditions

Liquid packaging machines can pack different types of items, such as dairy and meat products. Often, they need to be cleaned to ensure hygiene, so water and other cleaning fluids are used. For these reasons, the equipment must be resistant to water or detergent items required during the washing process. Otherwise, the machine will be damaged.

Therefore, choose a machine with a 5 to 8 IP rating. As you only clean the machines occasionally, so there is no need for an IP rating with the highest.

Dusty conditions

Conversely, if your packaging machines are used for powder and granule items, they can create a large amount of dirt, which can risk the electrical equipment. So, with dust control machines, you can keep them safe and running smoothly. The 5 to 6 IP rating should be enough for dusty conditions.

Both wet and dusty conditions

When you need a machine for work in wet and dusty conditions, choosing one with an IP rating of 55 to 68 is necessary. This will protect your equipment from dust and water jets. So you can pack liquid and powder items as well as clean the machine with water when needed.

How To Choose A Suitable IP-Rated Packaging Machine?

To choose a proper IP-rating machine, you should know the product’s characteristics. Check the below-mentioned features–

Test Your Product’s Viscosity & Moisture

Before selecting packaging machines, test the product’s viscosity and moisture level. For higher moisture, you need a machine with a high IP rating. At the same time, the high viscosity level requires strong equipment that can work with thicker or thinner content.

Besides, you can ask the manufacturer or supplier about the properties of your product so that they can guide you in choosing a machine.

Examine Your Bulk Filling Product Size

Choose a machine that matches your product’s size and type, as there are different types of machines available. For instance, if the product contains liquid, purchase a machine with IP rates that can withstand water.

Benefits Of Choosing An Ideal IP-Rated Packaging Machine

- Reduce Replacement: Generally, packaging machines are expensive and large, so when you buy one, you can think of running it for years to come. For this, you should choose equipment with the correct IP rating. Otherwise, you will stress about replacing the machine or any parts very often.

- Save Maintenance: An ideal IP-rated packaging machine matches your requirements and reduces maintenance, so you don’t have to provide extra care for it. For instance, if you choose a low IP rate machine, you can’t use it outside or handle water, which can require proper maintenance after use.

- Smooth Running: When you purchase the best IP-rating equipment, it will run smoothly. This means its bearing and other moving parts will operate smoothly, avoiding issues.

- Hygenic: Maintaining hygiene is crucial in the food industry. Therefore, the machine must be cleaned very often to ensure good manufacturing practices (GMP) grade. So, choosing an IP rate that can withstand water is necessary.

Conclusion

Hopefully, you know everything about the IP rating now. This will surely help you make an informed decision about buying a packaging machine. With ideal ingress protection, you can save your equipment from dust, water, weather, etc. Therefore, if you want the best IP-rated packaging machine, contact HonorPack ASAP.

FAQs

What is the best IP waterproof rating for a packaging machine?

The best IP waterproof rating for the packaging machine is between IP65 and IP68. Depending on your situation, you can choose one machine among these ratings. For example, if you clean the machine deeply, choose IP66. On the other hand, IP68 would be necessary for outdoor use.

How do you check the IP rating in the packaging machine?

To check the IP rating on a packaging machine, typically look for a label or sticker on the machine’s body or in the user manual. The label will display the IP rating, usually in the format IPXX, where the first X indicates protection against solids and the second against liquids.

What is the minimum IP rating?

Generally, IP4X and IP2X refer as a baseline for most horizontal and vertical surfaces in most indoor installations simualtenously. However, outdoor or damp locations require minimum ratings, like IP54 or IP66.