Have you ever wondered how snack foods, candies, and other products are packaged in perfectly sealed pouches? What types of machinery are behind this process? How do these machines help businesses ensure product quality and increase efficiency?

In this blog post, we will explore the different types of pouch packaging machines, their functions, and their applications in various industries. By understanding the machinery options available, businesses can make informed decisions when investing in packaging equipment to meet their unique needs. So, let’s dive in and uncover the world of pouch packaging machines!

What are the Key Types of Pouch Packaging Machines?

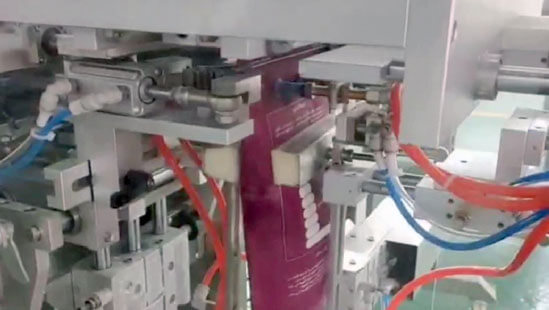

Pouch packaging machines are designed to form, fill, and seal pouches with various products. These machines come in different types, each suited for specific applications and packaging styles. Here are some of the most common types of pouch packaging machines:

- Vertical Form Fill Seal (VFFS) Machines: These machines form pouches from a continuous roll of film, filling them with product and sealing the pouches vertically. VFFS machines are versatile and can handle a wide range of products, including powders, granules, and liquids. Learn more about VFFS machines here.

- Horizontal Form Fill Seal (HFFS) Machines: Similar to VFFS machines, HFFS machines form pouches from a continuous film roll but do so horizontally. These machines are ideal for packaging larger products or multiple items in a single pouch. Find out more about HFFS machines here.

- Rotary Pouch Fill and Seal Machines: These machines use pre-made pouches, filling and sealing them in a rotary motion. Rotary pouch fill and seal machines can accommodate various pouch styles, including stand-up, flat, and zipper pouches. Discover the benefits of rotary pouch machines here.

- Vacuum Pouch Packaging Machines: Vacuum machines remove air from the pouch before sealing it, ensuring the product stays fresh and has an extended shelf life. These machines are commonly used for packaging perishable goods, such as meats, cheeses, and vegetables. Explore vacuum pouch packaging machines here.

- Sachet Packaging Machines: Sachet machines form, fill, and seal small pouches, typically used for single-use products like condiments, sugar, or coffee. Sachet machines can produce a variety of pouch styles, such as pillow, stick, and three-side sealed pouches. Learn more about sachet packaging machines here.

What Factors Should You Consider When Choosing a Pouch Packaging Machine?

When selecting a pouch packaging machine, there are several factors to consider:

- Product Type: Consider the product you plan to package – its size, consistency, and quantity – to determine the best machine for your needs.

- Pouch Style: Different machines can handle various pouch styles, so choose a machine that can accommodate your desired pouch design.

- Production Speed: Evaluate the machine’s production capacity to ensure it meets your production goals and can scale with your business.

- Budget: Determine your budget and compare the costs of different machines

to find one that offers the best value for your investment.

- Maintenance and Service: Consider the ease of maintenance, availability of replacement parts, and access to local service technicians to ensure your machine remains operational and efficient.

How Can a Pouch Packaging Machine Benefit Your Business?

Investing in the right pouch packaging machine can provide numerous benefits for your business:

- Efficiency: Automated packaging machines can significantly increase production speed and efficiency, reducing labor costs and minimizing human error.

- Consistency: Pouch packaging machines ensure consistent pouch quality, size, and appearance, enhancing your brand’s image and increasing customer satisfaction.

- Versatility: Many pouch packaging machines can handle a variety of pouch styles and sizes, allowing you to package multiple products with a single machine.

- Reduced Waste: Advanced technology and precise filling systems minimize product waste, saving on raw materials and reducing overall costs.

- Customization: Some pouch packaging machines can be customized to meet unique packaging requirements, ensuring the perfect solution for your business.

How Can HonorPack Help You Choose the Right Pouch Packaging Machine?

At HonorPack, we have over 20 years of experience in the bag packaging machinery industry. Our team of experts can help you navigate the complex world of pouch packaging machines, offering guidance on selecting the best machine for your specific needs. With our top-quality Korean manufactured products, competitive pricing, and customized packaging solutions, we can provide the perfect machinery to meet your unique packaging challenges.

In addition to our expert advice, we offer a one-stop-shop customer service experience, from machinery selection to delivery and installation. Our network of overseas dealers ensures that you receive local servicing and support, providing peace of mind and an excellent return on investment.

Conclusion

Understanding the different types of pouch packaging machines available is crucial for making an informed decision when investing in packaging equipment. By considering factors such as product type, pouch style, production speed, budget, and maintenance, you can choose the perfect machine for your business.

At HonorPack, we’re committed to providing high-quality, reliable bag packaging machinery that meets the unique needs of our clients. By partnering with us, you can trust that you’re investing in machinery that will not only meet your packaging requirements but also help your business grow and succeed.