Filling liquids into products used to be a headache, but now we have liquid packaging machine. It can fill various liquids into different packages such as bottle, pouch, sachet and capsule, and it is widely used in many industries such as food and beverage, chemical, pharmaceutical, cleaning, etc. It provides you with speed, convenience and reliability.

What is Liquid Filling Machine

A liquid packaging machine is a machine used for industrial packaging, used to package various liquids such as beverages, water, and oil. Generally, there are two types: automatic and semi-automatic. There are measurement and control systems to ensure the accuracy of the filling. The emergence of liquid packaging machines improves productivity, precision, and safety.

Liquid Filling Machine Working Principle

First, setting parameters such as speed, temperature, and pressure based on the liquid’s viscosity and other natures. Then loading bottles into a feed hopper where they are transported by rollers onto a conveyor belt that adjusts for different bottle diameters. The bottles to the filling unit employed mechanisms like pistons, gravity, pumps, or vacuum to precisely inject liquid from a reservoir into the containers. Finally, moving the bottles to the capping unit for sealing.

Depending on the production capacity, 1, 2, 4, 6, or 8 liquid fillers are available.

Liquid Filling Machine Automation Degree Classification

There are three classifications for liquid filling machines based on the degree of automation.

Manual Liquid Filling Machines

Manual liquid filling machines need human control all the time. There are no automated parts in it. The operation of them is very easy. You only need to set the filling volume by adjusting the screw and pull the lever to fill.

Semi-Automatic Liquid Filling Machines

They have more accuracy and flexibility than manual ones. Semi-automatic liquid filling machines have automated filling features. The operator needs to initiate and monitor the filling process. The efficiency is much higher than the manual liquid filling machines.

Fully Automatic Liquid Filling Machines

The fully automatic liquid machines have a high automation. They can work at high speed with minimal human intervention. The filling process is precise and consistent.

Two types of them are widely used. One of them is Inline Filling System. The operations of them are in straight line configuration. The other one is Monobloc Filling System, which integrates feeding, filling, sealing, coding, and labeling on the machine.

Types of Liquid Filling Machine

Filling machines can be categorized into single-head, double-head, and multi-head types, depending on your liquid packaging application.

Standard volume ranges (in ml) are:

| 10-100 | 30-300 | 50-500 | 100-1000 | 300-2500 | 1000-5000 |

Gravity Filling Machine

Gravity filling machine uses the material’s own gravity to fill the liquid into the containers. It is suitable for the liquid that has high fluidity. Like water, beverages, etc. The container of the machine does not need strict requirements for the containers. bottles, pouches, and so on can be used. This machine is convenient, fast speed, high precision and is ideal for large-scale production. This machine is based on time-control. And it is basically a type of volumetric filler.

Pressure Filling Machine

A pressure filling machine uses pressure to push the liquid into the container. The pressure is kept constant during the filling process and the liquid level is monitored by an automatically controlled level sensor. They are widely used for the liquid that is in medium viscosity. Like oils, sauces, lotions, etc.

They are also typically employed for liquids that are carbonated, such as soft drinks, beer, and sparkling water. They can help this kind of products to maintain the carbonation levels by minimizing foaming and gas escape.

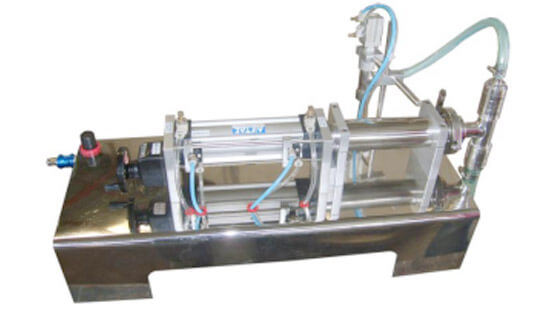

Piston filling machine

These liquid filling machines compress the liquids into a cylinder and then force them into containers using a piston mechanism. The filling volume can be changed based on the piston’s stroke length. And the movement of the piston can control the liquid volume. The flow of liquid materials is controlled by a check valve, and the stroke of the cylinder is regulated by a magnetic switch to adjust the filling volume.

This kind of machine is a great option for the products that have high viscosity and poor fluidity. Like ketchup, jams, gel, syrups, paste, etc. If you need certain precision, it is a excellent choice for you.

Flowmeter Filling Machine

The Flowmeter Filling Machine is a type of liquid filling equipment that uses flowmeters to measure and control the amount of liquid dispensed into containers. It makes sure that the liquid is measured by the flowmeter while passing through a pipe or hose and moved to the containers. This machine provides high accuracy, efficiency and accurate dosing. It is suitable for pharmaceuticals, cosmetics, chemicals, etc.

Weight Filling Machine

One difference from other filling machines is that these machines are designed to fill containers by weight. They use a weighing scale to measure and monitor the liquid product weight during the filling and after filling process. They can be used for filling liquid products with varying viscosities.

Pump Filling Machine

Pump filler is a type of volumetric filler. It employs different types of pumps to accurately dispense liquids into containers. The pump mechanism includes peristaltic pumps or rotary pumps. For the liquid that has high viscosity like cream and honey, they can’t be filled by their own gravity. Because they are viscous, they need extra power for filling. By using the pump, the valve, and other mechanical parts, the machine can fill the high-viscosity liquid.

Overflow Filling Machine

Overflow filling machines are designed to ensure that each container is filled with the liquid product to the same level, providing a uniform appearance on the shelf. They use diving nozzles to dispense liquids. Containers are moved into position under the filling heads by a conveyor The nozzles are lowered into the containers and liquid is pumped in, then creating a seal over the bottleneck. Once the liquid reaches the target level, any excess is diverted back into the reservoir through overflow nozzles, ensuring precise fill levels.

Vacuum Filling Machine

Vacuum filling machines work by using a vacuum pump to create a negative pressure inside the container, drawing the liquid material to the container under atmospheric pressure. The vacuum is released when the filling process is complete. This method not only increases filling speed but also prevents the liquid material from coming into contact with air, reducing the risk of oxidation and contamination.

Liquid Filling Application

Liquid filling machines have a wide usage area.

| Industry | Industry Based Features | Packaging Products |

| Food and Beverage | Easy pour spouts, resealability, barrier properties to extend shelf life | Vinegar, wine, juices, oils, sauces, beer, soda, milk, carbonated drinks, ghee, coffee |

| Pharmaceuticals and Medical | Tamper-evident seals, precise dosing capabilities, sterile packaging | Liquid pharmaceuticals, injections, syrups, oral liquids |

| Cosmetics and Personal Care | Leak-proof, single-use portions, UV protection to preserve ingredients | Perfumes, nail polishes, liquid foundations, shampoo, toners, serums, shower gel, facial cream, conditioners, lotion |

| Cleaning and Chemical | Chemical resistance, durable materials, controlled dispensing | Dishwashing liquids, floor cleaners, liquid soap, liquid fertilizers, lubricants, coolants, herbicides, insecticides, liquid chemicals, detergent |

Factors That Need to Be Considered

Types of Liquid Product:

Liquid viscosity and other characteristics may affect machine’s work. You must determine the type of fluid you need to fill.

| Viscosity of Liquid Material | Liquid Filling Machine | Liquid Products |

| low | Gravity filling machine | water, beverage, etc. |

| medium | Pressure filling machine | oils, sauces, lotions, etc. |

| high | Piston filling machine | ketchup, jams, gel, syrups, paste, etc. |

| varying viscosities | Weight Filling Machine | liquid products in different viscosities. |

Productivity:

The productivity of a liquid filling machine corresponds to your needs. If you only need small scale production, then you don’t need a high-productivity machine. While, if you need large scale production, you should choose a fully automatic liquid machine.

Adjustability:

Adjustable parameters are important, especially when you need to package different products. You need to adjust the different dosage amounts and rates for different products and packages.

Durability:

Your company’s longevity needs a reliable liquid filling machine.

Conclusion

Liquid filling machines offer speed, precision, and other things. With the introduction above, you can choose different liquid filling machines according to your needs, your product characteristics. A proper liquid filling machine can keep you competitive. So, if you are looking for liquid filling machine manufacturers, contact Honor Pack NOW!

FAQ

What are the energy supply methods for liquid filling machines?

In addition to small manual liquid filling machine manual power supply, electric, pneumatic, hydraulic power supply is widely used in the liquid filling industry

How is the digital control liquid filling machine controlled?

Data is transmitted to the PLC controller through various sensors (such as flow meters, pressure sensors, and level sensors). Operators use the HMI (Human-Machine Interface) to adjust parameters and control the filling process.

What is table top liquid filling machine?

Table top liquid filling machine is a semi-automatic filling machine. It is usually small and compact, suitable for small to medium-sized production. They use a set of calibrated pistons to apportion a precise quantum of liquid into a vessel.