Protein powder is a booming industry, with increasing demand in sports nutrition, meal replacements, and dietary supplements. Proper packaging is crucial to maintaining freshness, preventing contamination, and ensuring accurate portioning.

An automatic protein powder packaging machine can efficiently weigh, fill, and even dispense spoons, seal protein powder into jars, pouches, or sachets, optimizing production and reducing labor costs.

This guide covers everything you need to know about choosing the right protein powder packaging machine, including types, working principles, key features, cost considerations, and how to select the best machine for your business.

1. Why Invest in a Protein Powder Packaging Machine?

Manually filling and sealing protein powder is time-consuming and inconsistent. A high-quality automatic packaging machine offers:

✔ Accurate weighing & dosing – Ensures each package contains the correct amount.

✔ High-speed production – Packages thousands of units per hour.

✔ Hygienic and contamination-free packaging – Protects powder from moisture and bacteria.

✔ Customizable packaging options – Supports stand-up pouches, sachets, jars, and stick packs.

💡 Fact: A high-speed automatic protein powder packaging machine can fill and seal up to 60-120 packages per minute, drastically improving production efficiency.

2. Types of Protein Powder Packaging Machines

The right machine depends on your packaging type, production volume, and automation level.

1. Vertical Form Fill Seal (VFFS) Machine for Pouches

🔹 Best For: Protein powder in stand-up pouches, pillow pouches, or gusseted bags.

🔹 How It Works: Forms a pouch from a roll of film, fills it with powder, and seals it.

🔹 Features:

✔ High-speed production (30-100 bags per minute).

✔ Suitable for 100g – 5kg protein powder packaging.

✔ Works with plastic, laminated films, kraft paper pouches.

✅ Pro Tip: If you need higher-speed protein powder pouch packaging, choose a continuous VFFS machine.

2. Premade Pouch Packaging Machine for Premium Protein Powder

🔹 Best For: Premium protein powder brands using preformed pouches.

🔹 How It Works: Uses pre-made stand-up pouches, fills them with protein powder, and seals them.

🔹 Features:

✔ High-quality packaging for retail shelves.

✔ Supports zipper, spout, and flat-bottom pouches.

✅ Pro Tip: Ideal for premium protein powders that require aesthetic branding and reclosable features.

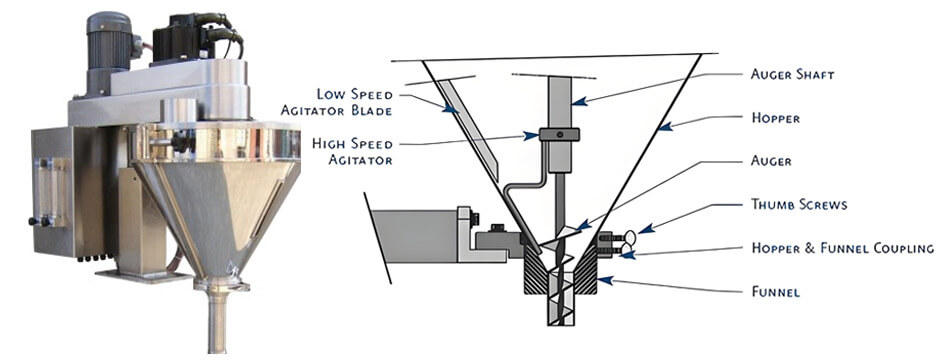

3. Auger Filling Machine for Jars & Bottles

🔹 Best For: Protein powder in plastic jars, tubs, or bottles.

🔹 How It Works: Uses a screw auger to dispense precise amounts into containers.

🔹 Features:

✔ High-precision dosing (±1% accuracy).

✔ Dust-free filling system to prevent contamination.

✔ Automatic scoop inserter – Places measuring scoops inside jars before sealing.

✔ Supports automatic capping and labeling integration.

✅ Pro Tip: If selling premium whey protein or mass gainers, choose a machine with integrated jar sealing.

4. Sachet/Stick Pack Machine for Single-Serve Protein Powder

🔹 Best For: Small, single-use sachets (10g, 20g, 30g).

🔹 How It Works: Fills and seals long, slim stick packs from a roll of film.

🔹 Features:

✔ Ideal for on-the-go protein powder packs.

✔ Reduces material waste compared to pouches.

✔ Suitable for pre-workout powders, BCAA, and collagen supplements.

✅ Pro Tip: Fully automatic compact stick pack machine has a small footprint, is inexpensive, and is suitable for small-scale production.

5. Multi-Lane Sachet/Stick Pack Machine for Small Packets

🔹 Best For: High-speed production of individual protein powder stick packs.

🔹 How It Works: Fills multiple sachets simultaneously, increasing output.

🔹 Features:

✔ Produces 4-10 stick packs at a time for maximum efficiency.

✔ Ideal for sample packs or travel-friendly portions.

✔ Works with heat-sealed paper, foil, or plastic sticks.

✅ Pro Tip: Mass production of stick packs for protein powder packaging, with sachet Sorting machine and cartoning machine at the back end.。

3. How Does a Protein Powder Packaging Machine Work?

A protein powder packaging machine follows these 5 key steps:

1️⃣ Powder Weighing & Dosing – A screw auger filler measures and dispenses powder.

2️⃣ Bag/Jar Forming – The machine forms a pouch (VFFS) or holds a container (jar filler).

3️⃣ Filling & Vibrating – The machine fills powder and removes excess air for better settling.

4️⃣ Sealing & Capping – The bag is heat-sealed, or the jar is capped and labeled.

5️⃣ Output & Quality Control – The final packages are checked for weight and integrity.

✅ Pro Tip: Machines with vacuum de-aeration systems help prevent powder clumping.

4. Key Features to Look for in a Protein Powder Packaging Machine

1. Auger Filler for Precision Powder Dosing

- Prevents overfilling or underfilling.

- Ensures uniform product weight in each package.

2. Dust Control System

- Dust extraction prevents airborne powder from contaminating machinery.

- Cleanroom-compatible design for food-grade packaging compliance.

3. Bag/Jar Compatibility

- Supports different packaging materials (plastic, laminated film, paper, glass).

- Zipper sealing, easy tear notches, and nitrogen flushing for freshness.

4. High-Speed Servo Motor for Accuracy

- Ensures smooth operation without material waste.

- Adjustable speed settings for different production needs.

5. PLC Touchscreen Control Panel

- Easy-to-use interface with preset filling programs.

- Real-time weight adjustments and error detection.

6. Automatic Scoop Insertion

- Places measuring scoops inside jars or pouches before sealing.

- Ensures consistency and enhances customer convenience.

✅ Pro Tip: Choose machines with 304/316 stainless steel construction for food safety compliance.

5. Choosing the Right Protein Powder Packaging Machine

| Factor | Considerations | Best Machine Type |

|---|---|---|

| Production Volume | Small, medium, or large output? | VFFS (medium-high), Jar filler (bulk production) |

| Packaging Type | Pouch, jar, stick pack? | VFFS (pouch), Auger filler (jar), Stick pack machine |

| Powder Accuracy | High-precision dosing needed? | Auger filler system |

| Branding Requirements | Resealable, stand-up, eco-friendly? | Premade pouch packaging machine, Jar filler |

✅ Tip: If selling bulk whey protein, opt for a jar-filling system.

6. Cost & Budget Considerations

| Machine Type | Estimated Price Range | Best For |

|---|---|---|

| Semi-automatic auger filler | $5,000 – $15,000 | Small businesses, startups |

| Sachet/Stick pack machine | $10,000 – $30,000 | Single-serve protein sachets |

| Automatic VFFS machine | $15,000 – $50,000 | Medium to large-scale production |

| Pre-made bag packaging machine | $20,000 – $60,000 | Premium, branded protein powders |

| Multi-lane sachet/stick machine | $50,000 – $100,000+ | Mass production of small sachets |

✅ Pro Tip: Fully automatic machines reduce labor costs and improve efficiency over time.

7. Finding the Best Protein Powder Packaging Machine Supplier

Look for a supplier that offers:

✔ Customization options – Tailored to different protein powder types.

✔ Strong after-sales support – Spare parts, maintenance, and training.

✔ Compliance with food safety standards – CE, ISO, GMP, FDA.

✔ Successful case studies – Proven track record in protein powder packaging.

🚀 Need help choosing the right machine? Contact HonorPack for expert advice!

8. Conclusion: Making the Right Choice

Selecting the best protein powder packaging machine depends on:

✔ Your packaging type (stand-up pouch, jar, sachet, stick pack).

✔ Your production speed & accuracy needs.

✔ Your budget and long-term ROI.