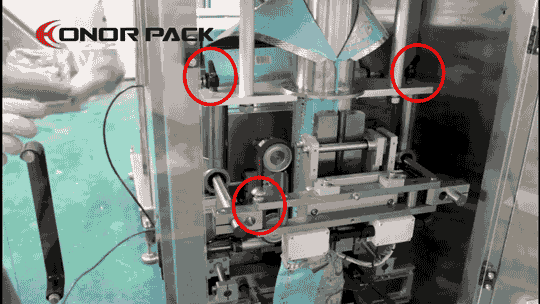

Fast Change Jaws

Fast Forming Tube Change

Graphic Touch Screen HMI

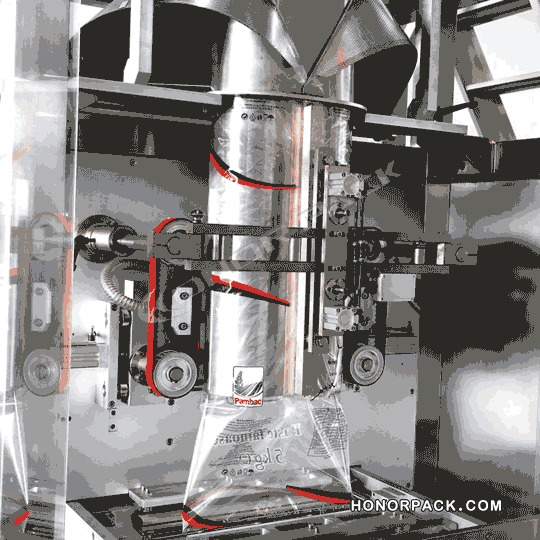

Servo & Vacuum Pulling

Safe Door Interlock Guard

Smooth & Low Noise

Perfect Film Rewinding

Servo Technology Jaws

Smooth operation in low noise

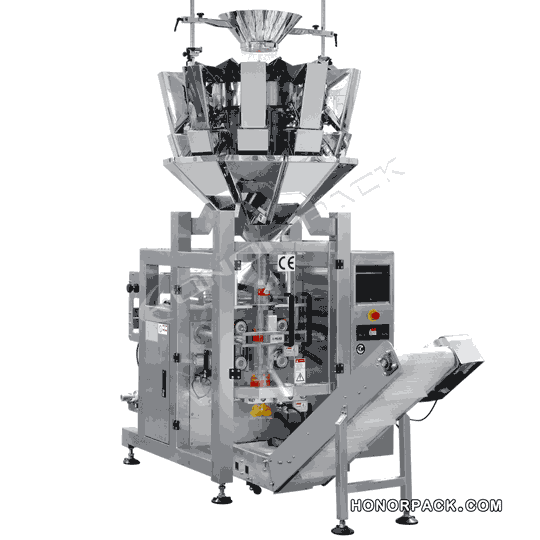

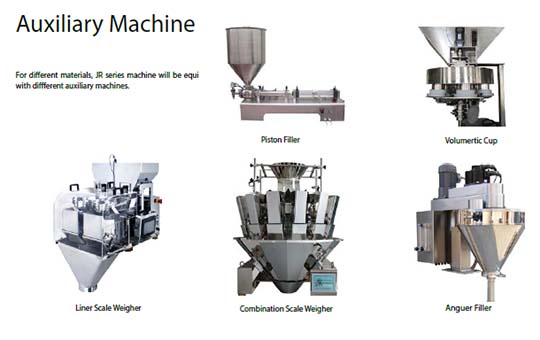

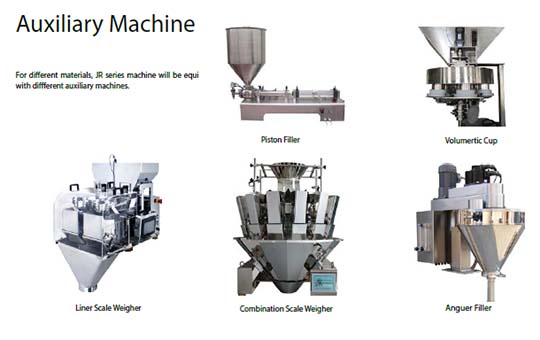

Versatile to filling system

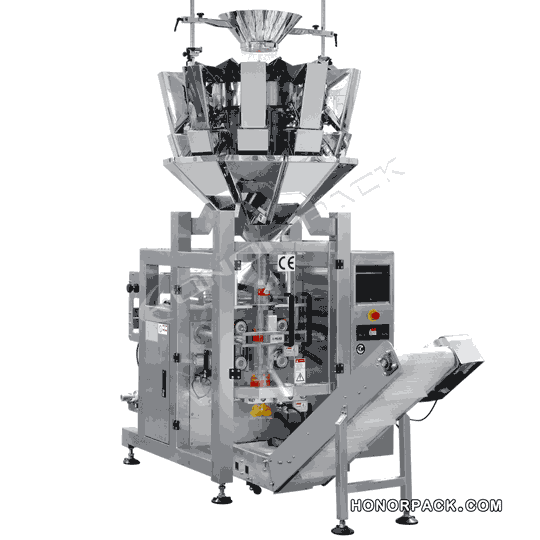

Weigh, Form Coding Fill & Seal, Output

Air Mandrel

EPC

8 Product Recipes

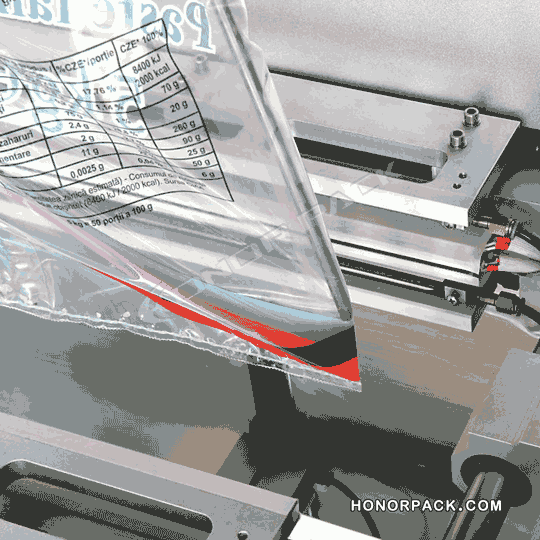

Fast Change Jaws

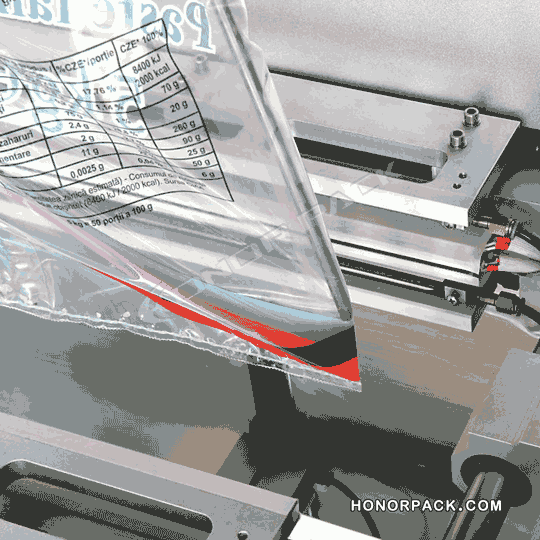

Change over for heat-sealable laminated film or polyethylene materials

Fast Forming Tube Change

Simple and fast forming tube change without tools

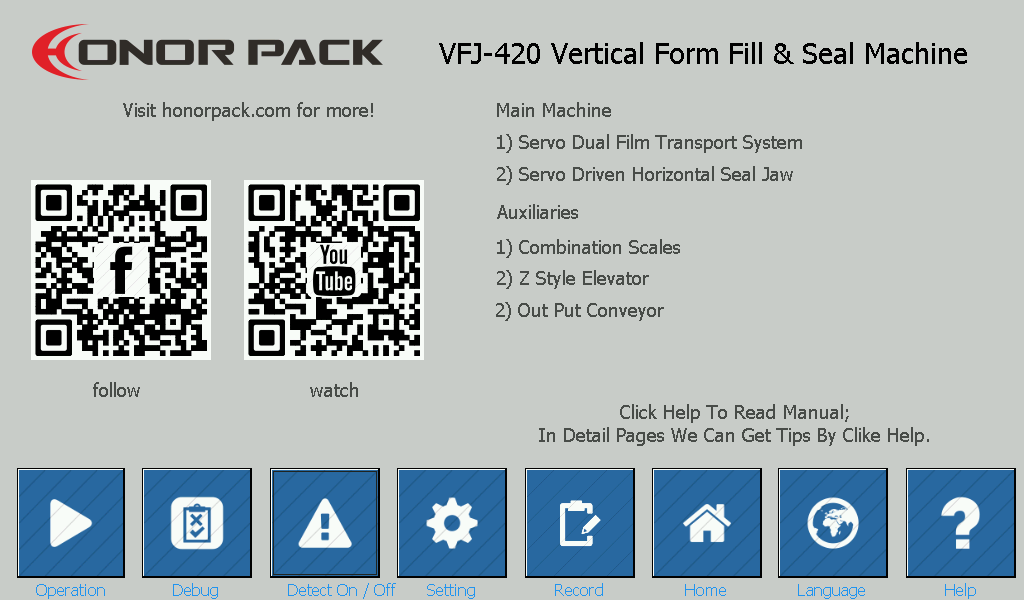

Graphic Touch Screen HMI

Intelligent control by PLC & Touch-Screen HMI with multi-languages

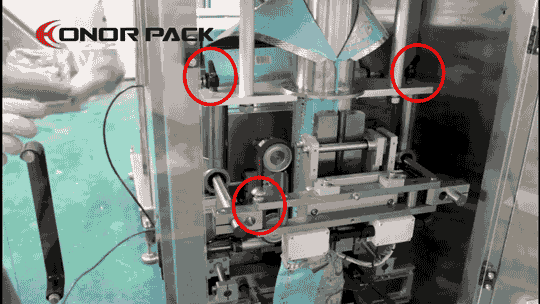

Servo & Vacuum Pulling

Dual servo system for film transport with vacuum pulling belts

Safe Door Interlock Guard

A safety door with interlock function, never can accesses to dangerous parts during running

Smooth & Low Noise

Perfect film tension rewinding for high-performance bagging

Perfect Film Rewinding

Perfect film tension rewinding for high-performance bagging

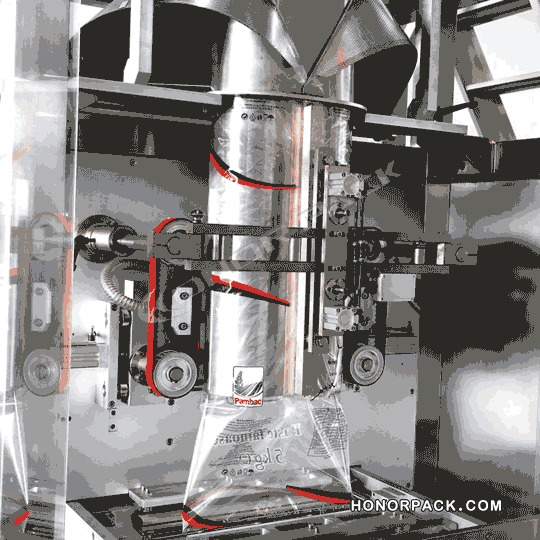

Servo Technology Jaws

Servo technology for reciprocation sealing l8

Smooth operation in low noise

Smooth operation in low noise

Versatile to filling system

Versatile to Synchronize any filling system

Weigh, Form Coding Fill & Seal, Output

Hot stamping, inkjet, thermal transfer & labeler.

Air Mandrel

More easy to change film web in air mandrel

EPC

Electric Position correct

8 Product Recipes

Storage for 8 product recipes