Piston filler handles low and high viscosity products. They also feature precise filling and have high operating speeds and flexibility. They are widely used in various packaging industries.

Next, I will use my 20 years of packaging experience to introduce to you the advantages, principles, types, and applications of piston filler.

The Overview of Piston Filler

A piston filler used to precisely pump liquid or semi-solid products into containers. It can handle both thin and thick products, and can fill a wide range of products such as beverages, ketchups, salad dressings, gels, lotions, toothpastes, peanut butter, honeys, and some soaps. As you can see, the piston filler can handle the products even with particles or chunks in them. Widely used in the food industry. The process is very precise and fast, ideal for packaging products that can spoil if not packaged properly.

The Benefits of Using a Piston Filling Machine

- Versatility: It can be used to fill thin liquids, thick liquids, for liquids of all viscosities, even pastes, creams and particulate products. This versatility makes it highly popular with the food industry. The piston filler has various sizes and types of nozzles, making it even more versatile. And it can fill containers of all sizes.

- High Fill Accuracy: Piston filling machines have high product fill accuracy. Precise dosage control can ensure uniformity, consistency of filling and reduce wastage. The consistent pressure and flow managed by the piston and valve system ensures each container is filled accurately. The high accuracy makes them highly favored by the cosmetic and pharmaceutical industries.

- Easy Maintenance and Cleaning: Piston filling machines are simple in design and many piston filling machines are designed with quick disassembly and cleaning functions for easy cleaning or maintenance.

- High-Quality Material: Many piston fillers are made with 316L stainless steel and high-quality USDA/FDA-approved materials. They are durable and meet strict hygiene standards.

The Working Principle of Piston Filler

In general, the filling of the product is achieved by the piston movement of the machine.

First, the product is fed into the hopper. Then the valve opens from the hopper to the cylinder, and the operator will step on a foot switch to start filling.

The piston is withdrawn from the cylinder to the required position. When the piston is drawn from the cylinder, the product will fill the cylinder to the drawn position. When the required position is drawn, the valve will rotate. By rotating, the valve between the cylinder and the nozzle will open, while the valve between the hopper and the cylinder will close.

The piston is then pushed back, pushing the product from the cylinder outwards, towards the nozzle and into the container to be filled. The volume of product required to be filled in the hopper does not change, so neither does the volume filled into the container.

This filling process is therefore very precise. You can determine the volume of product dispensed by adjusting the stroke length of the piston.

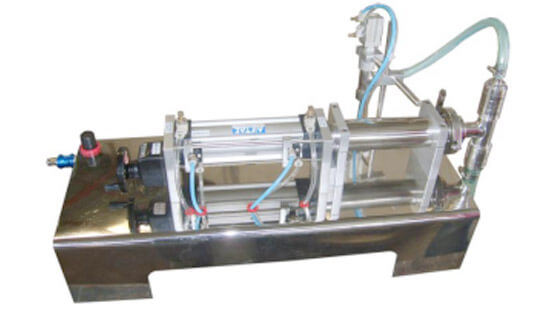

Main Parts of Piston Filler

- Hopper: Used to hold products to be dispensed, usually made of food-grade plastic or stainless steel to ensure product hygiene and safety. Can be equipped with agitators to ensure even product flow.

- Piston: The piston pumps the product into the cylinder and pushes it towards the nozzle and into the container later.

- Valve: Used to regulate the flow path of the product.

- Cylinder: This part goes through continuous suction and compression cycles and has constant volume to ensure stable and consistent filling.

- Nozzles: The nozzle dispenses the product into the container. The nozzle can prevent spillage or dripping during filling, reducing losses.

Different Types of Piston Filling Machines

Based on Configuration

- Rotary Piston Filler: The containers of a rotary piston filler move along a circular path, using a rotating platform. As each container rotates under the filling heads, a piston draws product from the supply and dispenses it into the container. This type of machine offers high continuity, precision and speed. Suitable for companies with large-scale production.

- Inline Piston Filler: Unlike rotary piston filling machines, the containers on inline piston filling machines move linearly. It has a high degree of flexibility. You can easily integrate an inline piston filling machine to your production line.

Based on the Number of Heads

- Single Head Piston Filler: Single head piston filling machine has only one filling head, can only fill one container at a time. Suitable for small-scale production use.

- Multi-Head Piston Filler: This type of machine has multiple filling heads. It can fill multiple containers at the same time. Improving production efficiency and making it suitable for mass production.

Based on Operation

- Check Valve Piston Filling Machine: The check valve piston filler works with a check valve. The filling valve is opened during the filling stroke. And after the filling is complete, the check valve on the filling side is closed and the discharge valve is opened at the same time, during the dispense stroke. The check valve piston filler is suitable for most free-flowing liquids, but not for thicker products or products containing particulates.

- Rotary Valve Piston Filling Machine: The rotary piston filling machine controls the flow path of the product by rotating the valve. By rotating the valve, the valve between the hopper and the cylinder is opened, while the valve between the cylinder and the nozzle is closed. The piston is then drawn to the required position and the product enters the cylinder. Then, by rotating the valve, the valve between the hopper and the cylinder is closed, while the valve between the cylinder and the nozzle is opened. The piston pushes the product out and the product is filled into the container through the nozzle. Rotary valve piston filler can fill products that are thicker or contain particulates like peanut butter, potato salads, and so on.

- Servo Driven Piston Filler: The servo driven piston filling machine uses a servo motor to control the movement of the piston filling. It has high precision, can more accurately control the movement of the piston, runs more smoothly, has high flexibility, and can better adapt to different product viscosities and container sizes.

Application

Piston filling machines widely used in various industries, I will introduce a part of these applications next.

| Industries | Production Examples | Machine Feature |

| Food and Drink | salsas, sauces, honey, syrups, peanut butter, nuts, beverage | can handle products of various viscosities, high speed and flexibility |

| Personal Care and Cosmetics | cosmetic creams, gels, heavy shampoo, toothpaste, creams and lotions | efficient and precise filling, can handle viscous products |

| Medical and Pharmaceutical | topical solutions and ointments | precise filling, high-quality material, hygienic |

Conclusion

Piston filling machines are versatile, reliable, efficient and accurate. Packaging machines with piston filler can packaging products of various viscosities. It is your good choice for filling liquids and pastes.