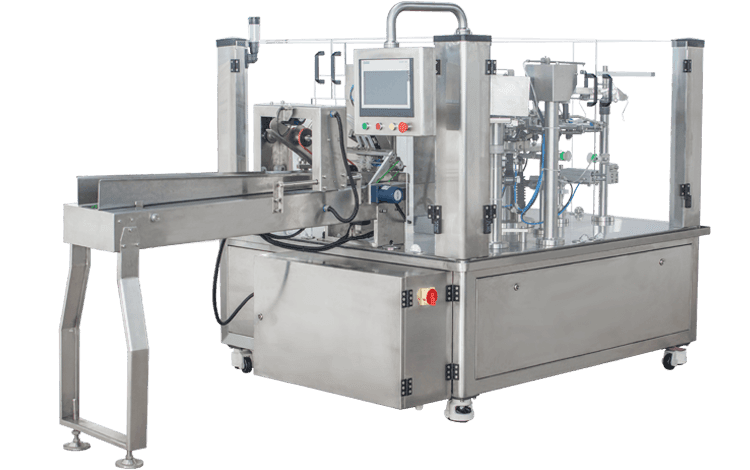

- Packaging Machine

- Case

- Application

- Video

- Knowledge

- Cut Costs & Increase Efficiency - Learn How With Our Blog

- About&Contact

Hello! Every one.

HonorPack sincerely appreciate customers from worldwide using our machines & process lines.

Engineers with long-time experience in the field of food and pharmacy industirals will provide not only the right machines also valuable producing solutions care for working environment and productivity with HACCP.

With our efforts to bring customer success, we honored to be the partner of SUMSANG and Korea govement project to help small business with automatic machine to replace the labor working.

We promise to march successful future together with customers under our intime and correct service !- 20+ Years of Experience

- Export to Over 50 Countries

- Korea Design China Prices

- Local After-Sale Service

- AGENTS

- TRADE SHOW

Interpack

May. 4-10, 2025

8bD80-8138th Canton Fair

October 15-19, 2025

19. 1K36 English