What’s the difference between overwrapping and flow wrapping? You may ask the question when you come across these two words. Well, you often encounter them in your daily life. From food and cosmetics to electronics, their applications are incredibly diverse. And you can easily find out that flow wrapping has a strong sealing and overwrapping is often used for secondary packaging. In the following section, I will provide a detailed introduction to their differences and applications.

What is Flow Wrapping

Flow wrapping, also known as horizontal flow wrapping. It is suitable for packaging products of many shapes. Wrapped in polyethylene (PE), polypropylene (PP) or polyethylene terephthalate (PET) material. The film is transparent or custom printed. Sealed at both ends. It is airtight and has a total barrier seal. Widely used in pharmaceutical and candy industries.

What is Overwrapping

Overwrapping is suitable for packaging flat products, such as paper boxes, DVD boxes, cigarette boxes, etc., unlike flow packaging, which can package products of various shapes. It is often considered more attractive, so it is also used as a gift box. Overwrapping is usually used as secondary packaging. It can hold many individual packages.

Working Process

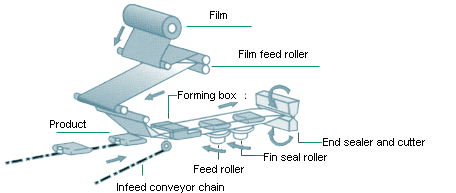

Working Process of Flow Wrapping Machine

Flow wrapping machines can pack products of various shapes. Here is the working process of the flow wrapping machine.

- Feed the products and move them to the forming zone: The product is fed into the flow wrapper by a conveyor belt. Then move the products to the forming zone.

- Forming: When the product enters the packaging area, the film is guided into a “U” shape. The product passes through the center of the film. The film wraps around the product, forming a tubular structure underneath. Wrap the products with the film.

- Sealing: Using the heat and pressure to create a tight seal. The sides of the film are heated and passed through pressure rollers to create a longitudinal seal, forming a closed tube.

- Cutting: Cut the packaging into individual packs.

- Discharging: Discharge the packages for storage.

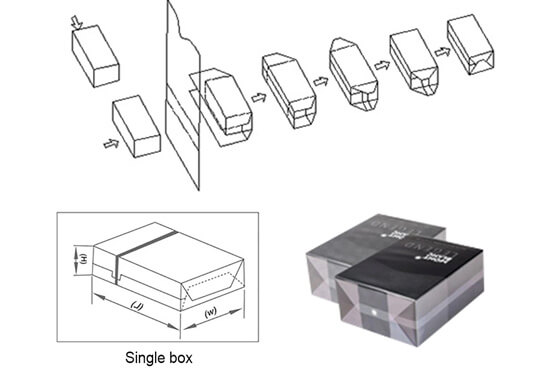

Working Process of Overwrapping Machine

- Move the product through the film.

- Fold the film around the product: The folding process is similar to wrapping a gift. The film is folded around the corners and edges of the product.

- Sealing: Heat seal on the overlapping part. The ends of the film are folded and tucked in to create a neat and secure package. Heat or pressure is usually applied through a heated seal bar.

- Cooling.

- Discharge the packages and move for storage.

Key Differences Between Flow Wrapping and Overwrapping

Shape of Products

Flow wrapping has high flexibility and can be made in various sizes. So it is suitable for packaging products of different sizes and shapes. In contrast, overwrapping is only suitable for products with flat edges. It is ideal for more regular items like boxes. As a result, it is often used for secondary packaging. By the way, you can package your gift with it.

Sealing Property

Flow wrapping is airtight and has a total barrier seal. Its sealing capability is superior. It can effectively block air and moisture. Helps maintain product freshness and extend shelf life. This level of protection is especially important for perishable goods, pharmaceuticals, and sensitive electronics. While overwrapping is not a complete barrier wrap. Because the folding seal method cannot guarantee complete airtightness.

Material Cost

Flow wrapping has a higher packaging utilization rate. While Overwrapping using about 20% more film. Additionally, the materials used for Overwrapping may be more expensive than those for flow wrapping. These two features make overwrapping have higher material costs.

Operational Flexibility and Efficiency

Flow wrapping has a faster production speed compared to overwrapping. It is suitable for high-speed production. Additionally, flow wrapping is simpler to set up and offers flexible configuration. That allows them to have quick and efficient switching between different products. Adjusting for various sizes and shapes is also more convenient.

Visual Appeal

Compared to flow wrapping, overwrapping has a more refined and streamlined appearance. Create a smooth package look that can showcase more intricate designs. In addition to custom patterns, the outer packaging film can also feature elegant branding elements, logos, and other details. This makes it an ideal choice for packaging products like cosmetics, tea, coffee, and cigarettes.

Anti-Tampering

Overwrapping can create an excellent tamper-evident seal, ensuring the integrity of the product. It can make your products safe from tampering. Any tampering is easily detected. Because the seal is typically created only by the overwrapping machine. Overwrapping needs specialized equipment to apply correctly. And because overwrapping uses a folding seal, any tampering becomes more obvious. This anti-tampering feature is crucial in industries like pharmaceuticals and food, where product safety and authenticity are paramount.

On the other hand, replicating the original seal of a flow-wrapped item is relatively easy. So the flow wrapping can be tampered more easily. And the product can be damaged more often.

Flow Wrapping Application

Flow wrapping has a fast production speed, strong sealing, and excellent barrier properties. And It can accommodate products of various shapes and sizes. Due to these characteristics, it becomes a popular choice across many industries. Let me introduce you to its applications. And adjusting for various sizes and shapes is convenient.

| Industries | Examples of Products | Packaging Features |

| Food and Confectionery | chocolate, candy, snack bars, bakery products, cookies, perishable food | strong sealing, excellent barrier properties, fast production speed |

| Cosmetics and Personal Care | soap, lotion, toothbrushes | strong sealing, excellent barrier properties |

| Pharmaceuticals | medicine, syringes, gloves, bandages, plasters | strong sealing, excellent barrier properties, safe |

| Hardware | screws, nails, and other fasteners | can package products of many shapes and sides, simpler to set up and offers flexible configuration, Adjusting for various sizes and shapes is also convenient |

| Office Supplies | paper documents, pens, markers, notebooks | fast production speed |

Overwrapping Application

Overwrapping can create an excellent tamper-evident seal. Ensuring the integrity of the product. And it has a more refined and streamlined appearance. It can hold other packages in overwrapping. You can see them in the following products.

| Industries | Examples of Products | Packaging Features |

| Food, Drink, and Confectionery | chocolate box, tea box, coffee beans box, box of tea bags | an extra layer of protection, visual appeal, can hold other packages |

| Pharmaceuticals | medicine boxes, blister packs of tablets or capsules | tamper-proof |

| Tobacco Products | cigarette packs | protection against moisture, tamper-proof |

| Cosmetics and Personal Care | soap box, lipstick, paper towels box, perfume box | good looking, more refined appearance, tamper-proof |

| Electronics | phone box, computer box, TV box | extra protection, tamper-proof |

Conclusion

After reading this article, it should be easier for you to decide which packaging to use based on the characteristics and key differences between flow wrapping and overwrapping. Flow wrapping has strong airtightness and has the ability to package various shapes of products. It is ideal for packaging food and is widely used in hardware and other industries. On the other hand, overwrapping is better suited for secondary packaging. Its tamper-evident sealing makes it a popular choice in industries such as pharmaceuticals and electronics.