Have you ever wondered how snack food packages are perfectly sealed? How do these machines manage to create airtight packaging, ensuring product freshness and safety? In this blog post, we’ll dive into the world of sealing machines and explore how they work.

A sealing machine, simply put, is a device that seals packages by applying heat and pressure to create an airtight seal. These machines play a crucial role in various industries, particularly in food packaging. Let’s take a closer look at the process and the different types of sealing machines available.

Stay with us as we unravel the intricacies of these essential machines, which contribute significantly to the packaging industry.

What Are the Main Components of a Sealing Machine?

The main components of a sealing machine include the heating element, pressure mechanism, conveyor system, and control panel. These parts work together seamlessly to ensure a smooth and efficient sealing process.

- Heating Element: This component generates heat to melt the packaging material, creating a bond between the layers. The temperature must be carefully controlled to avoid damaging the product or packaging.

- Pressure Mechanism: The pressure mechanism applies consistent pressure to the heated material, ensuring a strong, airtight seal.

- Conveyor System: This part transports the packages through the sealing process, maintaining a steady flow and keeping up with production demands.

- Control Panel: The control panel enables the operator to set and adjust various parameters, such as temperature, pressure, and conveyor speed, to optimize the sealing process.

How Do Different Types of Sealing Machines Work?

There are several types of sealing machines, each designed to cater to specific packaging requirements. The most common types include impulse sealers, continuous band sealers, and vacuum sealers.

Impulse Sealers

Impulse sealers use a short burst of electrical current to generate heat, melting the packaging material and forming a seal. The machine’s sealing bar heats up quickly and cools down just as fast, making it suitable for thermoplastic materials such as polyethylene and polypropylene[^1^]. Impulse sealers are available in various sizes, making them versatile for different packaging needs.

Continuous Band Sealers

Continuous band sealers work by passing the packaging material between heated bands, which create a continuous seal[^2^]. These machines can handle a wide range of materials and are particularly suited for high-volume production lines. The conveyor system feeds the packages through the machine at a consistent pace, ensuring a steady workflow and uniform seals.

Vacuum Sealers

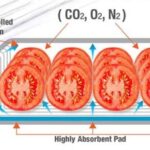

Vacuum sealers remove air from the packaging before sealing it, creating a vacuum environment that helps to preserve the product’s freshness[^3^]. This type of machine is popular in the food industry, as it extends the shelf life of perishable items. Vacuum sealers typically use a combination of heat and pressure to create a strong, airtight seal around the product.

What Factors Affect the Sealing Process?

Several factors can influence the effectiveness of the sealing process, such as temperature, pressure, dwell time, and material properties.

- Temperature: The correct temperature is crucial for achieving a strong, reliable seal. Too much heat can damage the packaging or product, while too little heat will result in a weak seal.

- Pressure: Consistent pressure ensures a uniform seal across the entire package. Insufficient pressure can lead to leaks or an incomplete seal.

- Dwell Time: This is the amount of time the material is exposed to heat and pressure. It must be carefully calibrated to achieve the desired seal strength without damaging the packaging.

- Material Properties: Different materials have varying melting points and require specific temperatures and pressures for optimal sealing.

How Can Sealing Machines Be Customized for Specific Needs?

Yes, sealing machines can be customized to cater to the unique requirements of different industries and products. Customization options include adjustable temperature settings, pressure controls, and specialized sealing mechanisms. For example, at HonorPack, we offer customized packaging solutions tailored to our clients’ needs, ensuring that our machinery delivers optimal performance and efficiency.

Custom Temperature Settings

Different materials have unique melting points and require specific temperatures for optimal sealing. Custom sealing machines can be equipped with adjustable temperature settings, enabling users to fine-tune the process based on the packaging material being used.

Custom Pressure Controls

Adjustable pressure controls allow operators to modify the pressure applied during the sealing process. This customization is essential when working with varying package sizes and materials, ensuring a consistent seal across all products.

Specialized Sealing Mechanisms

Some industries may require specialized sealing mechanisms to meet specific packaging requirements. For instance, medical and pharmaceutical packaging often necessitates sterile seals to protect the contents from contamination. In such cases, custom sealing machines with unique sealing mechanisms can be developed to cater to these demands.

What Are the Benefits of Using a Sealing Machine?

Sealing machines offer numerous benefits for businesses in the packaging industry, including efficiency, cost savings, product protection, and improved shelf life.

- Efficiency: Sealing machines streamline the packaging process, allowing for a higher output and faster production rates.

- Cost Savings: Automated sealing machines reduce the need for manual labor, resulting in lower labor costs and increased productivity.

- Product Protection: Airtight seals created by sealing machines help protect the product from external contaminants and preserve its freshness.

- Improved Shelf Life: Vacuum sealing machines, in particular, can extend the shelf life of perishable products by removing air from the packaging, slowing down the oxidation process, and inhibiting the growth of bacteria.

Conclusion

Sealing machines are an integral part of the packaging industry, providing efficient and reliable solutions for creating airtight seals. By understanding how these machines work and the various factors that affect the sealing process, businesses can optimize their packaging operations and achieve better results. At HonorPack, we are committed to delivering high-quality, customized sealing machines that meet the unique needs of our clients, ensuring a favorable return on investment and long-lasting partnerships in the bag packaging machinery industry.