Economical and efficient packaging solutions using film-formed bags, along with the compact and space-saving nature of VFFS machines, have made them widely applicable across various industries.

Do you want to understand how Vertical Form Filling Machines work? Would you like to learn about the functions and features of the components of VFFS Machines? In this article I will introduce you to the packaging process of the Vertical Form Filling Machines, from the rolled film to the finished bag.

Vertical Form Fill and seal Machine working principle

The Vertical Form Fill and Seal Machine, also known as a collar type filling and sealing packaging machine, is suitable for packaging various materials such as granules, powders, liquids, and pastes in pouches. The machine forms rolls of plastic film into bags, then measures the predetermined weight or volume of the product using a metering system before sealing the bag, creating a complete package.

Film Unwinding / Film Pulling

Roll film is unwound through an external film release device and pulled by a servo motor conveyor belt.

- Automatic film alignment function: The machine automatically adjusts the film to ensure proper alignment and prevent packaging misalignment.

- EPC (Edge Position Control): The EPC system is used to adjust the center alignment of the film. Pressing the “left” or “right” key moves the film frame to adjust the position of the film, aligning it with the center of the former.

- Control panel: Operators can adjust the tension and tracking of the film through the touch screen to ensure correct unwinding of the film during the forming process.

Code Printing

The coder is suitable for plastic film, PP, OPP, paper bags, labels, etc., integrated into VFFS machines to print batch numbers, production dates, and expiration dates on the film as it passes through the machine.

#1 Set the horizontal and vertical sealing bars, as well as the date coder, to the required temperature to ensure that the ink adheres correctly to the packaging material.

#2 Synchronize the printing speed of the coder with the packaging speed of the machine.

Bag Length Setting

Set the target bag length through the control panel, adjust the servo motor drive speed to pull the film. When setting the bag length on a VFFS machine, the following factors need to be considered:

Choosing Film Positioning Method:

Film Positioning has two options selectable on the touch screen: color mark length (photo-electric eye) and encoder length.

Color mark length (photo-electric eye):

Usually, printed films have color marks on them. The photo-electric eye detects these color marks on the film. The bag length is determined by the distance between color marks. The cutting position of the film can be adjusted based on the color mark points to avoid cutting into the printed design.

Encoder length:

Choosing encoder length allows direct modification of the packaging length on the screen. The length is detected as it scrolls, immediately changing the size of the bag produced (changing the bag width requires changing the forming unit). The length of the cut film is correct, but the cutting position cannot be adjusted, which may result in cutting into the printed design of the film.

First and Second Pull Film

When the bag needs to stretch the film twice, set the second stretch length here (total stretch length = first stretch length + second stretch length).

Consider Film Resistance

There is frictional resistance between the film and the machine, which affects the actual packaging bag length. (Thicker films have greater resistance).

If the packaging bag length does not reach the set accurate length, adjust the correction data until the desired true length is achieved.

Material Elevating / Weighing

VFFS packaging machines are equipped with lifting systems and measuring systems for material lifting and weighing.

Material Lifting System:

Transports the packaged material from the ground to the weighing hopper above the packaging machine. It can be divided into granular, powder, and liquid/paste types.

Granular material: Z-type elevator, Large slanting elevator, single-bucket elevator, bucket elevator

Powder material: screw elevator, vacuum elevator

Material Weighing System:

The material is lifted to the hopper and measured according to the set packaging weight.

The most commonly used measuring systems are:

Combination scales (for weighing granular, flake, block, and strip materials, including candies, cookies, coffee beans, chips, nuts, frozen foods, vegetables, etc., with fast speed and accurate measurement).

Screw metering machines (for powders such as flour, coffee powder, protein powder, additives, etc.).

2-head/4-head/6-head linear scales (for fine granules or coarse powders, rice, sugar, salt, laundry detergent, coffee powder, with a wider measurement range than combination scales, acceptable accuracy, slightly slower speed than combination scales, tailored to different materials).

For liquids or pastes, piston filling machines are used (or servo-controlled rotary pumps for high accuracy, wide range, fast speed, but higher price).

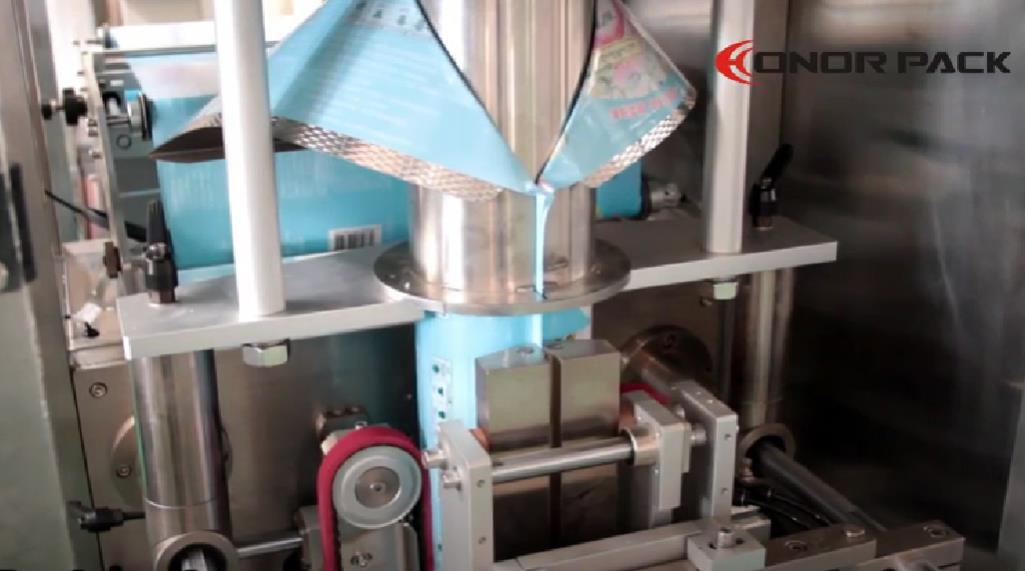

Bag Forming

After the film is unwound, it is stretched and cut according to the set bag length, and then formed into bags using different forming collar devices. Operators can change the width of the packaging bags by replacing different forming devices.

The edges of the film overlap vertically and are heat-sealed together to form the back seal of the packaging bag. Different back seal forms are available for selection through the settings of VFFS machines.

Bag Filling and Sealing

The dosing feeding system delivers materials into the packaging bag forming area. After the bag is filled, the sealing clamp seals the top of the bag, creating a top seal for one bag and a bottom seal for the next bag.

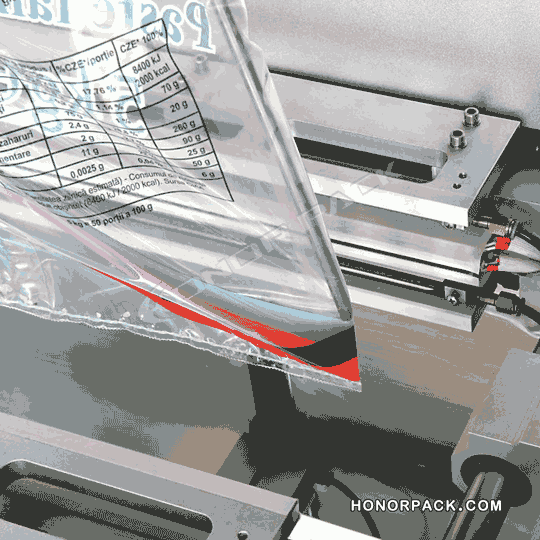

Here are the characteristics of bag sealing:

- Adjustable sealing time and pressure settings of the sealing jaws ensure the quality of bag sealing.(The thickness of different films will affect the speed and effectiveness of film melting and sealing.)

- The heavy-duty jaw assembly is equipped with a buffer for shock absorption and noise reduction.

- The sealing station can independently adjust the temperature, which is crucial for controlling the sealing temperature for both horizontal and vertical seals. This is applicable to different types of heat-seal films. (For composite film sealing, constant temperature heating rods are used for sealing; PE film is sealed using instant heating of resistance wires, requiring precise temperature control—too high a temperature can melt PE film, while too low a temperature may result in inadequate sealing.)

- Optional features include edge folding device (creates folds on the packaging bag), punching device (butterfly holes, round holes, handle holes), and nitrogen flushing device (for product preservation).

Bag Output

The cutting device of the machine separates the sealed continuous packaging bags, and the cut packaging bags are transported via a conveyor belt to downstream equipment such as pallets, checkweighers, metal detectors, boxing equipment, etc.